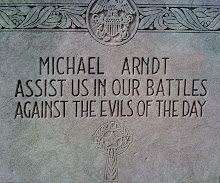

Posted by: Michael Arndt on October 05, 2009

For years Kraft Foods has been supplying cookies, crackers, and other snacks to vending machine operators. Now the food company is getting into the business directly, with its own network of automated dispensers. And, I should add here, these machines are unlike any you’ve ever dropped coins into.

I’ve just learned that Kraft is about to expand into direct-to-consumer distribution with about 30 vending machines in the Northeast next month. The company is reserving 15 of the device’s 55 “spirals” for its own products, such as Oreos and Planters peanuts. It’s offering the rest to other snack or candy makers.

If results of the experiment turn out favorably at year-end, Kraft and its partners will install machines in transportation hubs, colleges and universities, and health-care facilities elsewhere, says a spokeswoman, Angela Wiggins. She calls the new machine “a mini-convenience store.” Actually, it seems more like a mini-electronic billboard.

Today's snack machines typically have a large glass window showing all the goodies inside. The new Kraft "diji-touch" equipment, created by Samsung, replaces the window with a 46-inch LCD touch screen. By tapping on icons on the screen, a customer can get a 360-degree look at any snack, find out its nutritional info, or its ingredients.

The interactive screen works the other way, too. Vendors can display ads for their products on the front of the machines. Other sponsors can buy screen time as well. A college, for instance, might use the vending machines to spread the word about upcoming events.

The computerized devices are linked so that vendors can see when and where goods were bought. That way, they can learn more about customers' habits—do people buy fewer Cakesters after looking up their calorie count?—and test ad messages to find out which trigger more purchases, just as they can on the Internet.

A third-party such as a transit authority or hospital will own and maintain the machines, which are made by Crane Merchandising Systems, while Kraft will manage the digital media. Kraft will have access to all sales data during the test, even from rival vendors. But after that, each company will get info on only their own products, Wiggins tells me.

The touch-screen machines will not stock soft drinks. Samsung has set aside its uVending technology for that market for Coca-Cola, which is rolling out its own next-generation dispensers in shopping malls in the U.S. now.